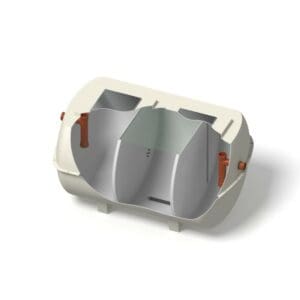

Marsh Shallow Ensign Standard 8 Sewage Treatment Plant

Size: 8 population

£3,522.00 inc. VAT

Marsh Shallow Ensign Standard 8 sewage treatment plant – 8 population

Marsh Ensign sewage treatment plants are widely regarded as one of the most efficient, reliable and economical systems on the market.

Common sewage treatment plants on the market often exceed 2.3m high. Marsh Industries offer a range of shallow plants from 4-35PE that are only 1.6m in height, meaning installation is not only possible, but easier and safer too.

Shallow Ensign sewage treatment plants are often favoured when hard rock site conditions mean deeper alternatives, involving costly and time-consuming excavation.

Designed to treat household wastewater for properties with up to 8 inhabitants, the Marsh Shallow Ensign:Standard is widely regarded as one of the most efficient, reliable and economical sewage treatment plants on the market.

Class leading performance

Tested and approved to BSEN12566-3/A1:2009 all Ensign units provide treatment well within national consent requirements. Published test results of 11.5:19.2:8.4mg/ltr (BOD:suspended solids:ammonia), with influent concentrations on test higher than those chosen by most competitor plants, effectively equates to 97% pollutant removal.

Unrivalled choice

Ranging in size from 4 to 35 PE in Ultra and Standard versions of each, and with a wide range of ancillaries, almost all site, consent and budget requirements can be met.

- Optional risers to increase invert depth are available

- Optional pumped outlets are also available

Why choose the Marsh Shallow Ensign:Standard?

End users, merchants and installers alike recommend the Ensign range due to its ease of installation, reliability, and cost-effective operation and maintenance. All backed by technical support from local contacts.

- Inlets and outlets with ‘Forsheda seal’

Forsheda seals provide flexibility in the joint for easier installation. - Low-energy compressor with alarm

Near silent compressor ensures minimal running, maintenance and servicing costs. Integral alarm detects low pressure in air line. - External compressor housing

Supplied as standard on all shallow and pumped outlet models. - PVC pressure pipe/diffuser(s)

Provides a protective conduit for the air diffuser line. Can be easily removed for maintenance and cleaning. - Bio-media

High specification bio-media (310m3 per m2) and membrane diffusers ensure even circulation to eliminate ‘dead spots’. - Nylon mesh

Retains media in aeration chamber during transportation and handling, and in the event of flooding. - 32mm sludge return

Larger diameter sludge return prevents the possibility of blockages and improves system circulation. Provides higher effluent quality whilst balancing flow over a 24 hour period or periods of intermittent use. - Impermeable lid

Regular lid/frame improves strength and durability whilst blending into the surrounding environment. - Integral lifting eyes

For safe and secure on-site handling. - Stabilising feet

Stabilising feet prevents the tank from rolling and allows safe and steady transportation and installation. - Unique ‘keying-in’ lip

Assists anchoring into granular or concrete surrounds.

Operating Principle

The tank utilises a three-chamber design to produce its high-quality effluent. The first chamber is where primary settlement takes place and where anaerobic digestion produces clarified water. This water then filters into a second aeration chamber where, supported by diffused air and bio-media, bacteria treats the effluent to remove the dissolved constituents. The third chamber is where final settlement takes place before the effluent is discharged into a drainage field or local watercourse.

Shallow Ensign:Standard

Population Equivalent (PE): 8

Length (mm): 2860

Width (mm): 1912

Height (mm): 1600

Inlet/Invert depth (mm): 500

Inlet Size (mm): 110

Please find below additional information you can download

Marsh Ensign Shallow Tank 8PE (Rev.A)

Marsh Industries – Sewage Treatment Manual 0520-RevG

Delivery charges depend on the region/postcode delivered to.

England & Wales

Standard delivery is £7.50 + VAT

Delivery on orders over £250 are free.

Scotland

Postcodes AB, DD, DG, EH, FK, G, HS, IV, KA, KW, KY, ML, PA, PH, TD and ZE the standard delivery is £10.00 + VAT.

For all other postcodes, please contact the sales team for details.

Please note that for larger, heavier items offloading is the responsibility of the customer.

For tanks and other large items delivered directly to your site, you will need suitable equipment available on the day of delivery to unload them from the lorry.

For more information on offloading, delivery lead times and our general delivery policies, please visit our Delivery & FAQs page.

Customers were also interested in these similar items...

Expertise You Can Trust

Approved Installers

Complete Installation Solutions

Top Customer Service

Did you know? We also offer UK-wide installation

When it comes to installing drainage, off-mains waste water treatment and pump stations, we've got you covered from A to Z. With years of experience under our belt, we take pride in being your comprehensive drainage specialists, honing our expertise.

What Our Customers Say

Brilliant from beginning to end Kevin and team very efficient and informative always quick to respond to any queries. Highly recommend the team on site polite and very professional really pleased

Nicola M.

Very helpful staff giving good advice, quick delivery of the 3 pumping stations we ordered which was as described on there website

Michael W.

Great company to do business with. Keen prices, reliable delivery and exceptional after sales service. Just a shame more companies can’t manage to keep up.

John J.

I have been using Drainstore for the last 4 years. They have always been great with their customer service and technical advice to make sure you get the right tank for the specific site conditions.

Chris B.

Reviews

There are no reviews yet.